Polycarbonate siding, also known as twinwall and multiwall polycarbonate sheets, is a durable plastic material with a long list of potential uses. Although polycarbonate siding is often used to construct greenhouses, it is also used for window replacements, light covers, carports, windbreaks, and more.

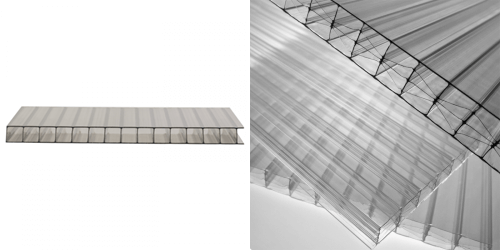

This type of siding comes in two primary varieties – twinwall, and multiwall. Twinwall sheets provide great strength for their value and look like two sheets of polycarbonate that are reinforced with evenly spaced strips of polycarbonate, creating a cell-like appearance. Multiwall sheets resemble twinwall sheets, except they provide additional protection by providing more plastic reinforcement within the cells.

By choosing twinwall or multiwall polycarbonate siding for your next project, you’ll enjoy a range of physical properties that make polycarbonate a great translucent building material. Let’s take a closer look at the primary benefits of polycarbonate.

Impact Resistance

Even in its most simple sheet form, polycarbonate is one of the strongest consumer plastics available. It can sustain high impacts without denting, cracking, or peeling, earning it a reputation as being virtually unbreakable. However, the design of twinwall and multiwall polycarbonate only further reinforces that strength by distributing the impact between multiple layers of polycarbonate.

As a result, polycarbonate siding is especially popular in scenarios where durability and long-term sustainability is a concern. For example, a greenhouse wall that’s made of polycarbonate will not shatter if a rock or other projectile hits the siding. However, if the greenhouse were made of glass, it would need immediate, expensive repairs.

[wbcr_snippet id=”534″]

Variable Light Transmission

Polycarbonate siding has a light transmission rate ranging from 20 percent to 80 percent but always offers 99.5 percent UV protection. This is beneficial in several ways – for example, a carport made of siding with low light transmission can prevent sunlight from heating or damaging your car’s interior by providing it with shade. On the other hand, a building made of clear polycarbonate siding will effectively trap heat – making it ideal for greenhouses.

It is also worth noting that the UV protection inherent in polycarbonate siding will prevent it from physically or aesthetically degrading. Both twinwall and multiwall will not yellow, discolor, or even become brittle with prolonged exposure to UV rays.

Weather & Temperature Resistance

One of the best properties of polycarbonate is its extreme resistance to the elements. With an operating temperature range of -40F to 212F, it can sustain almost any weather conditions without being damaged. It has a flame-spread rating of 25, meaning that it will not catch fire under almost any circumstance. For reference, cement is a non-flammable material with a rating of 0, and red oak’s rating is 100. Instead, polycarbonate will likely melt if it is exposed to heat over 225F.

When searching for materials with similar resistances, the only siding material that can hold a candle to polycarbonate are metals. However, polycarbonate siding is far more weather resistant than metal, as it will not corrode or otherwise weaken with prolonged exposure to moisture.

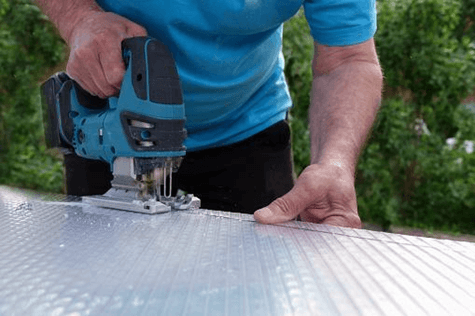

Lightweight

As a material, polycarbonate is exceptionally durable for its weight. A polycarbonate panel can easily be moved and arranged by human hands, while large sheets of metal can be challenging to move around on a jobsite. This makes them exceptionally simple and cost-effective to install. As a result, polycarbonate siding is popular among DIY users who do not want to enlist the help of friends or pay laborers to help them install the siding.

Not only that, but the lightweight nature of polycarbonate makes an entire structure far less heavy. This allows small structures to be transported easily and effectively if needed. As well, it opens the door for creative, new designs, as polycarbonate can provide a strong framework without putting stress on other parts of the building.

Sustainable

Polycarbonate is a thermoplastic – meaning after it reaches the end of its useful life, it can be melted down into a liquid. From there, it can be reshaped into a fresh, new form as needed. This makes polycarbonate siding an excellent choice for builders that are concerned with sustainability – not only will it outlast many other materials, it can easily be repurposed if it is damaged.

As well, polycarbonate siding can be cut to the exact size needed for your project. This ensures that builders aren’t wasting materials from the outset, which happens quite often when builders need to cut wood or metal sheets to exactly the right size.

Final Thoughts

Polycarbonate siding is growing in popularity among both amateur and professional builders due to a range of exceptional properties. It offers the durability of materials like metal siding while being far more lightweight than wooden alternatives. Best of all, polycarbonate’s asking price as never been more reasonable, making it an accessible building material for both consumer and commercial use.

Looking to purchase polycarbonate siding for your next project? Take a look at our selection of twinwall and multiwall polycarbonate. Or, if you have any questions, contact us today.